The Latest Innovations in Industrial Scales You Must Understand about

The Latest Innovations in Industrial Scales You Must Understand about

Blog Article

Top Attributes to Look for in High-Quality Industrial Scales

In the realm of commercial operations, selecting the right scale is vital for making certain efficiency and accuracy. Key features such as accuracy and accuracy, in addition to longevity and build quality, play a significant role in identifying the viability of a range for details applications. Furthermore, factors to consider like lots capability, ease of usage, and connection choices additionally enhance functional efficiency. Recognizing these aspects is crucial for making a notified choice, yet numerous organizations ignore essential facets that might influence their productivity. A closer assessment of these features reveals insights that could transform industrial considering methods.

Accuracy and Accuracy

Making sure the precision and accuracy of industrial ranges is extremely important for effective procedures throughout various fields. Precise dimensions are important in sectors such as manufacturing, logistics, and food handling, where also minor inconsistencies can bring about significant economic losses, compromised product top quality, or regulative non-compliance. High-quality commercial scales are made to deliver reliable performance, making use of innovative technology to assure specific weight readings.

The calibration procedure is necessary in keeping the accuracy of these ranges. Normal calibration against certified referral weights ensures that any type of drift in measurement is fixed, thus promoting conformity with market criteria. In addition, making use of high-resolution load cells boosts the scale's capacity to spot minute weight modifications, further enhancing its precision.

Durability and Construct Quality

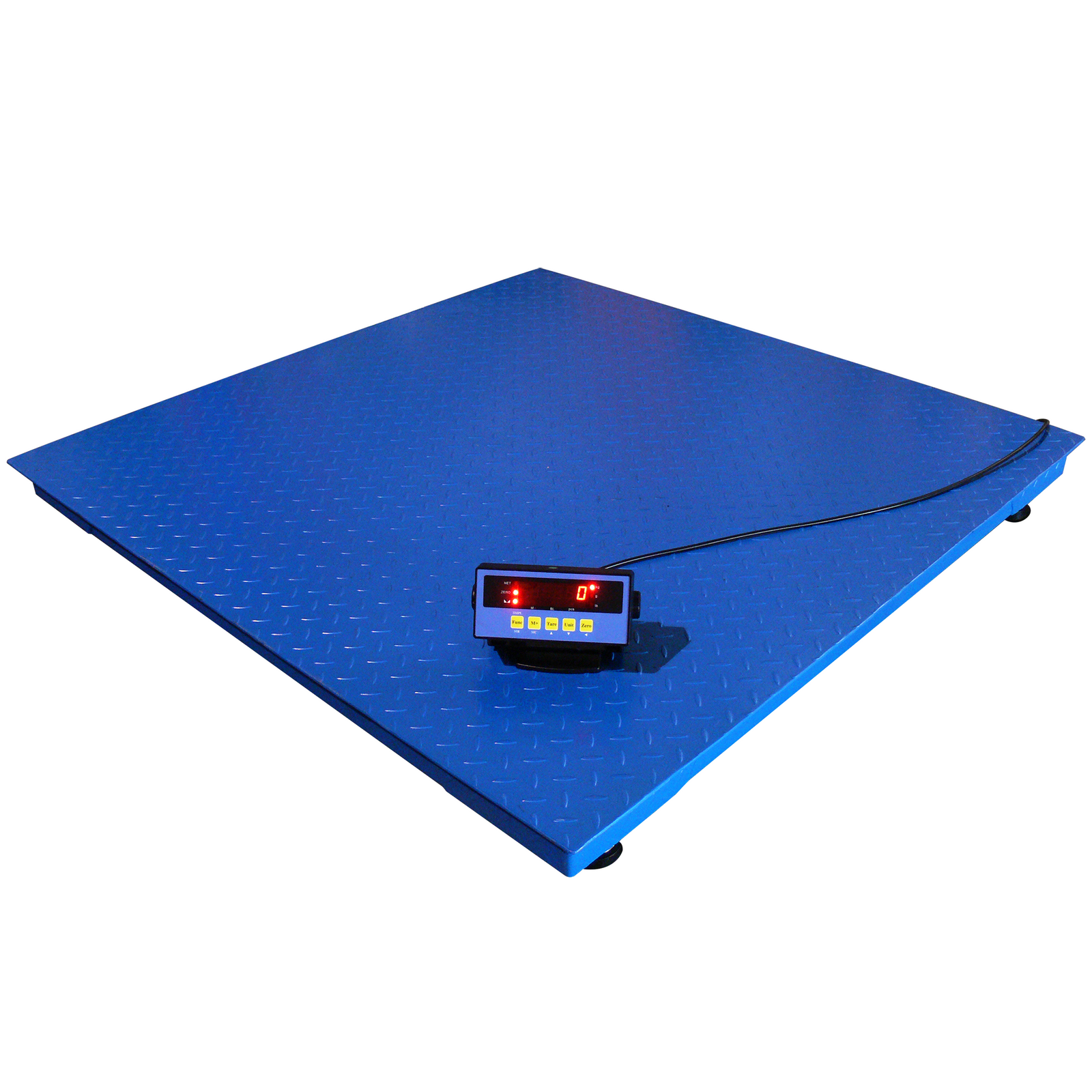

Resilience and build quality are important variables that determine the durability and reliability of commercial ranges sought after settings. Industrial ranges are frequently based on harsh problems, including exposure to dirt, moisture, and heavy loads. Consequently, the materials used in their building play a vital role in guaranteeing they can endure these obstacles.

Top notch industrial ranges typically include robust real estates made from materials such as stainless-steel or light weight aluminum, which not only offer structural honesty but likewise stand up to deterioration and wear. Additionally, attention to information in the layout, such as strengthened edges and shock-absorbent feet, can enhance longevity and safeguard delicate elements from damage.

Furthermore, state-of-the-art parts, including tons cells and digital components, add to the overall develop top quality. These components should be designed to endure temperature level variations and resonances generally located in commercial settings. Guaranteeing appropriate ingress security (IP ranking) is also crucial, as it shows the scale's capability to endure dirt and fluid exposure.

Inevitably, selecting industrial scales with superior durability and develop high quality will result in an extra dependable, resilient remedy that fulfills the rigorous demands of different commercial applications.

Tons Capability and Array

When picking industrial scales, understanding their load capability and range is necessary for meeting certain operational requirements. Lots ability refers to the optimum weight that a scale can accurately gauge, while the array suggests the spectrum of weights the range can take care of effectively. It is crucial to choose a scale that not only fulfills existing requirements however also fits possible future needs.

Different industries have one-of-a-kind weight measurement requirements. For example, a production center might call for scales efficient in evaluating hefty equipment parts, while a lab may only require scales this contact form for lighter materials. Selecting a range with an appropriate tons ability makes certain accuracy and accuracy, preventing overwhelming that could cause tools damages or imprecise readings.

Furthermore, it is vital to take into consideration the step-by-step level of sensitivity of the scale within its variety. A range that can determine both light and heavy weights accurately can boost operational effectiveness, permitting for functional applications. Purchasing ranges with proper tons capacity and variety considerably adds to productivity, compliance with sector requirements, and total operational content dependability. Consequently, complete assessment of these requirements is essential before procurement.

Convenience of Usage and Maintenance

Along with user-friendliness, simplicity of upkeep is an additional vital facet to consider. Ranges that are created with easily accessible parts assist in regular maintenance jobs such as cleaning, calibration, and battery replacement. A modular design can even more improve these procedures, enabling fast repair services and marginal downtime.

In addition, the products used in the building of commercial scales play a considerable role in maintenance. Scales made from durable, corrosion-resistant materials are easier to tidy and less vulnerable to damage, which expands their life-span and decreases general functional costs.

Normal upkeep routines, assisted by the manufacturer's suggestions, are important for making sure optimum performance. By focusing on convenience of usage and maintenance, services can make certain that their commercial scales remain effective, trustworthy, and reliable tools in their procedures. This leads to boosted performance and a more reliable workflow.

Connection and Combination Alternatives

Incorporating commercial ranges right into existing operational structures is considerably improved by durable connectivity options. High-quality industrial scales must supply several connectivity techniques, consisting of USB, Ethernet, pop over to this site and wireless options such as Wi-Fi or Bluetooth. These features facilitate smooth information transfer to central data sources, ERP systems, or cloud systems, allowing real-time surveillance and reporting.

Moreover, advanced assimilation choices enable compatibility with existing tools, such as printers or barcode scanners, streamlining processes and boosting process effectiveness. Scales that sustain industry-standard procedures, such as Modbus or RS-232, can quickly interact with various gadgets and systems, guaranteeing a natural operational atmosphere.

Another crucial facet is the capacity to integrate with software options that evaluate and picture information - Industrial Scales. Scales geared up with APIs or software application growth sets (SDKs) give businesses the adaptability to tailor functionalities customized to their specific needs

Lastly, considering future scalability is crucial; selecting ranges that can adjust to advancing technological developments makes certain long-term worth and reduces the demand for pricey substitutes. In summary, assessing connectivity and combination alternatives is essential when choosing top quality commercial scales that will improve functional performance and data administration.

Conclusion

In verdict, selecting high-quality industrial scales demands cautious consideration of several important features. Industrial Scales. Focusing on these qualities inevitably leads to boosted performance and long-term value in industrial applications, reinforcing the value of informed decision-making in scale selection.

In the realm of industrial procedures, choosing the right scale is important for ensuring effectiveness and precision.Guaranteeing the accuracy and accuracy of industrial ranges is extremely important for effective operations throughout various sectors. Tons ability refers to the optimum weight that a range can precisely determine, while the variety indicates the range of weights the scale can handle successfully. A manufacturing facility might need scales capable of considering heavy machinery parts, while a laboratory might just require scales for lighter materials. By prioritizing convenience of use and upkeep, businesses can make sure that their industrial scales stay efficient, reputable, and efficient tools in their procedures.

Report this page